The RACOmatic® CONTROL. This optimizes the performance and life of the RACO electric actuator.

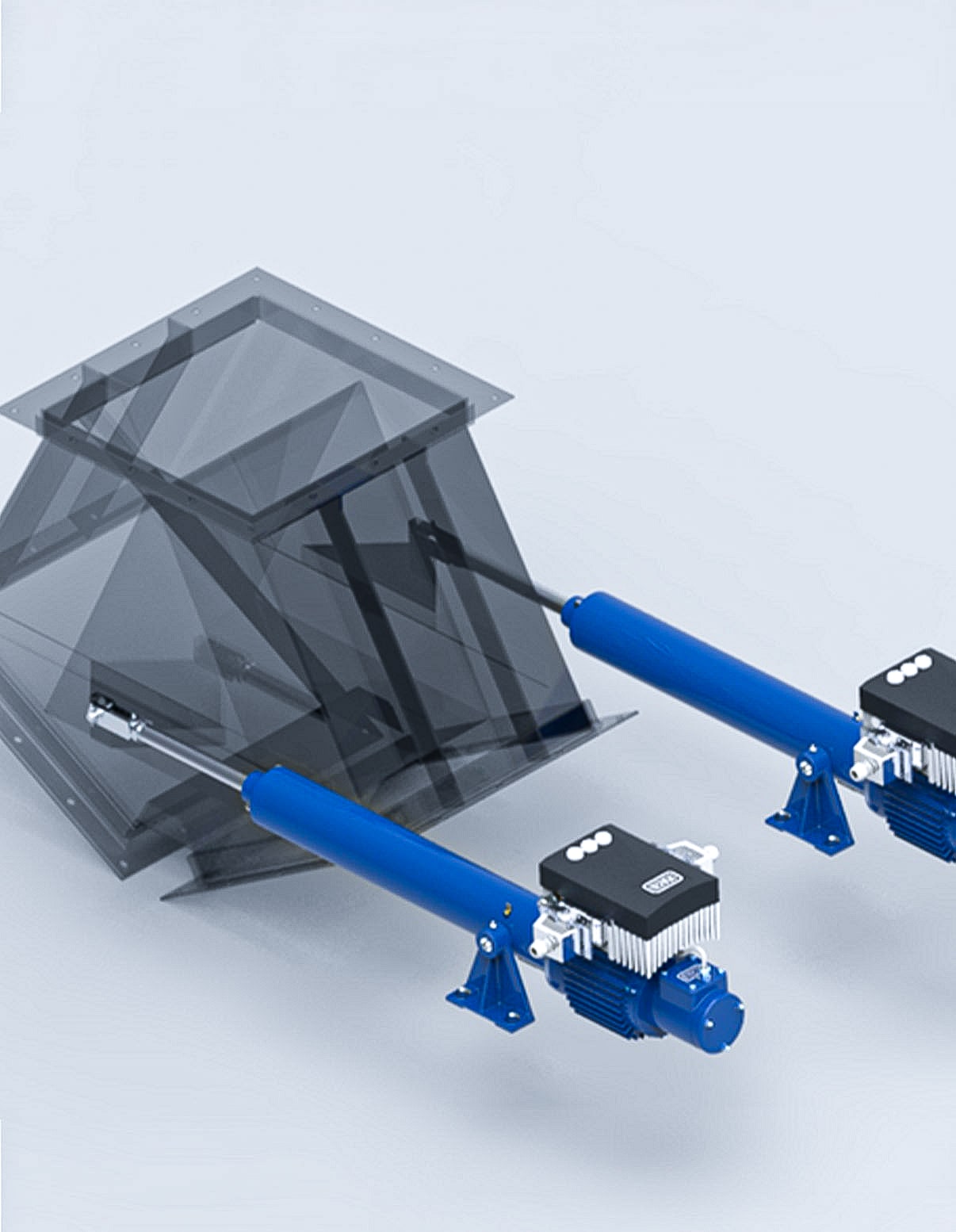

When it comes to maximum process reliability and consistent production quality, precise, fully repeatable motion control is necessary in today’s automation environment.

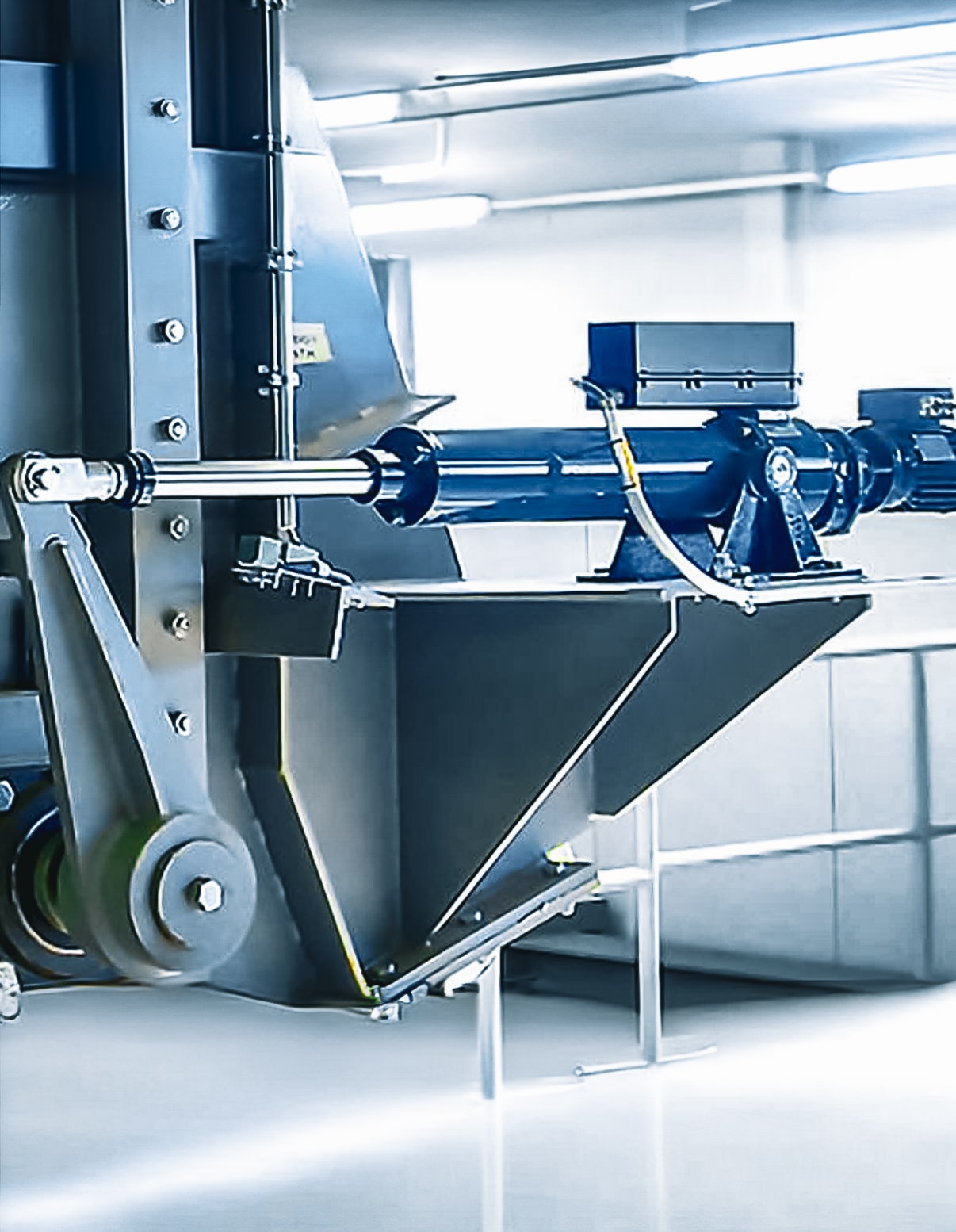

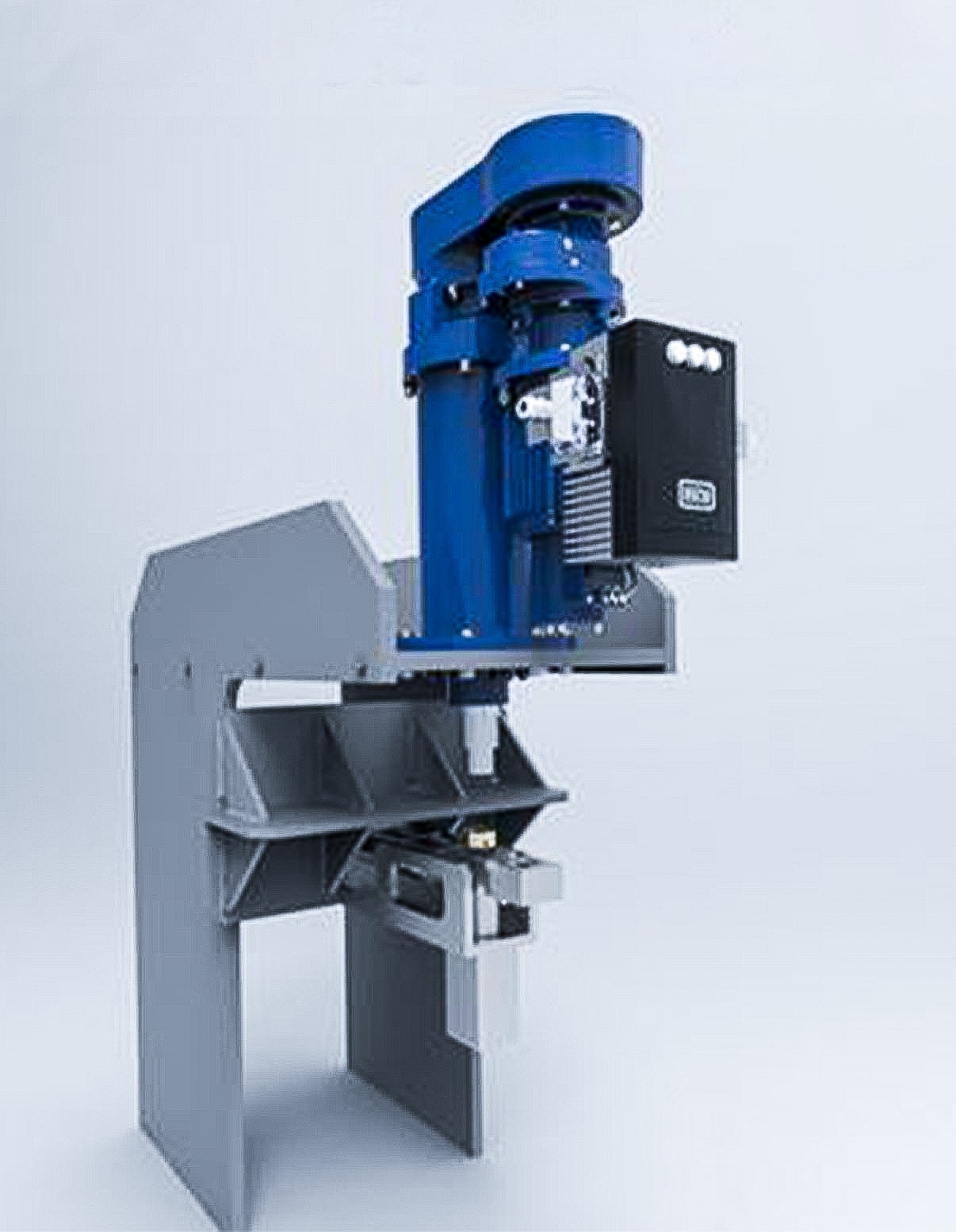

The RACOmatic® control system expands the functions of RACO Electric Actuators® into ready-to-use, turn-key integrated actuators. Mechanical components, software, and sensors are perfectly matched to the system architecture and the respective operation of the system. This provides a customized solution for every movement profile across a wide range of performance classes and designs for various applications.

Precise Positioning

Several intermediate positions and the two end positions are repeatable.

Customized Speed Profiles

Adjustable acceleration and deceleration ramps for maximum productivity.

Adjustable Thrust up to the Set Maximum Force

Adjustable limit values for the actuating force in the extension/retraction direction.

Actual Position as Analog Signal

In addition to digital signals, an analog signal is also available as an output value.

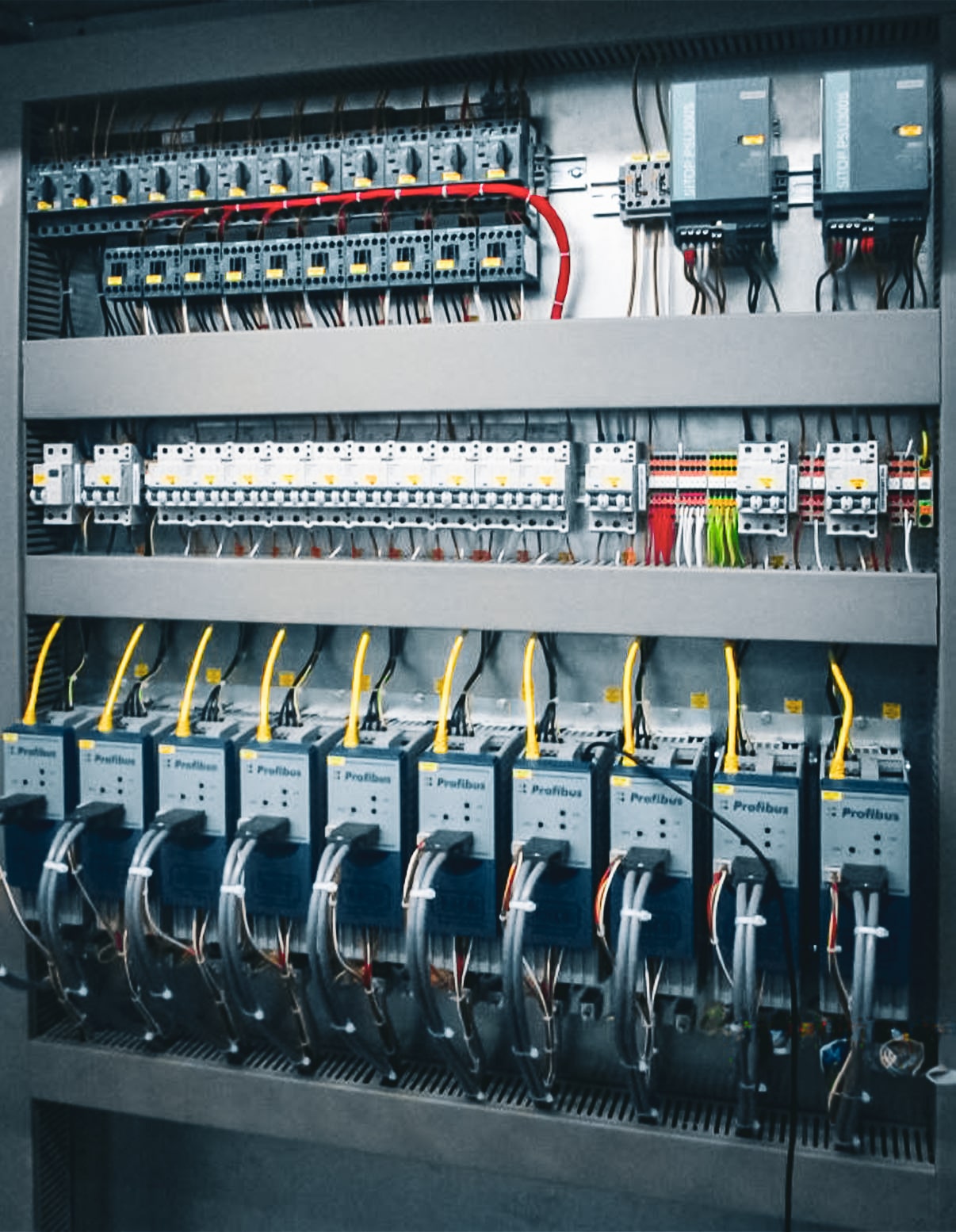

Fieldbus Interface

Modern Profinet communication allows for control of up to 24 electric actuators.

Multi-Axis Systems

Micro PLC with touch panel for the exact synchronization of up to 4 electric actuators.

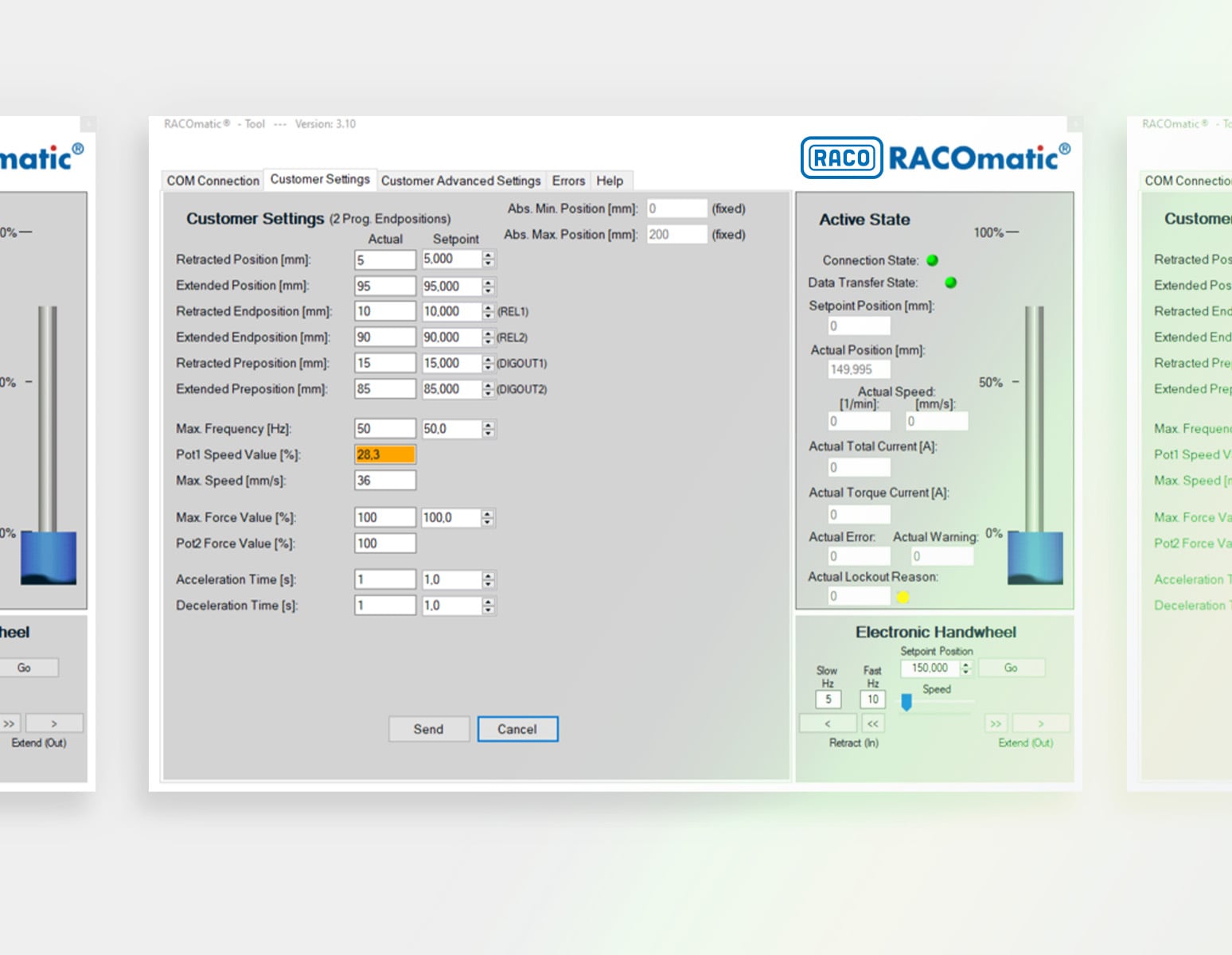

RACOmatic® Tool - Precise Control

The RACOmatic® Tool parameterization and diagnostic software for Microsoft Windows makes commissioning and functional testing of your RACOmatic® electric actuator intuitively easy. For example, the software allows you to set speeds and positions and define acceleration and deceleration, and braking ramps - all within the maximum permissible values. To protect the mechanics of your systems, maximum forces can be defined and a force switch-off can be programmed for emergencies.

The majority of these control variables are already set at the factory, and the parameters required for daily use are available to you quickly and easily for the operation of the relevant movements.

A MEASURABLE INCREASE IN PRODUCTIVITY, AVAILABILITY, AND FLEXIBILITY.

The keys to this are the high-precision force, acceleration and position control, and the ability to be integrated into all common control systems. The user-friendly interface ensures simple adjustment of the operating parameters.